digital geometry

academic

course

type

date

team

iaac, master in advanced architecture

digital fabrication

fabrication prototypes

fall 2020

robyn catherine-houghton

sneha vivek

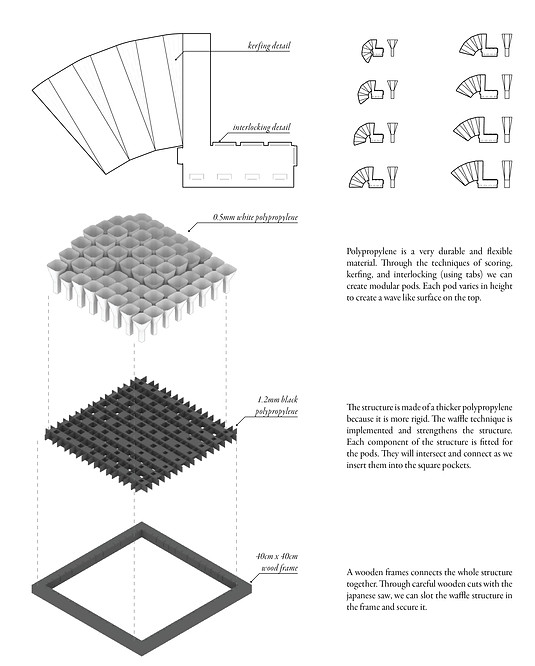

The project explores new fabrication techniques through the relation between the computer and the machine. Through the course, we design through the capabilities of three digital fabrication tools: laser cutter, CNC milling machine, and 3D printer. With these machines, our task is to develop modular components in various scales of architectural elements: a tile, a surface, and a panel.

From digital to physical, we explore the possibilities and limitations of how we design and communicate the connections between the two systems. We begin with basic designs that we fabricate for prototyping. This informs us the necessary changes for the next prototype.

laser cutter

Through the laser cutter, we design through quick prototyping. The performance by privacy for this project demands to develop a geometry that explores a variety of density, openings or elements that allow or prevent lines of sight.

cnc

The cones are made from High Density Foam and they allow for the absorbtion of sound. Its hard surface and porous properties can deflect sound waves. The base is made from EVA Foam, which is a much softer material than the HDF and can absord sound waves. A combination of the two materials can be used to decrease sound levels while absorbing it. The sound waves reflect through the cones and delfects the waves to the soft base.

The techniques used to CNC are a combination of horizontal roughing (for cutting away as much material as possible) to parallel finishing (a finishing that is smooth and clean). By using a 12mm flat mill bit, we reduce the timing of the mill in the horizontal roughing stage. The next stage is parallel finishing which we used a 6mm ball mill. The textures that are created on each material is a the result of its properties and the drill bit used. The cones have a ridge-like texture, while the foam has a rug-like texture.

3d printing

The particular challenge of this project is the creation of a complex aggregation patterning that incorporates light filtration through repetition and variation. To this aim, we explored computational tools that allow for parametric design of the elements. The geometrical pattern allows different penetrations of light. The undulation of the surface manipulates the light as it enters through the structure.

The material is white transparent ABS filament. Light is manipulated as it enters through the patterned surface because of the materiality. A soft illuminance is visible because of the properties of the filament.